Source: 663highland, CC BY-SA 3.0, via Wikimedia Commons

[Kimono Style] Why are Kimono so Expensive?

- Source:

- © JAPAN Forward

- Tags:

- Kimono

Related Article

-

Where to buy Yukata in Japan for an affordable price?

-

Shoeface: Repurposing old kimono, scarves and other fabrics into quirky shoelaces

-

Kimono fashion enthusiast creates amazing Pokémon-inspired kimono outfits

-

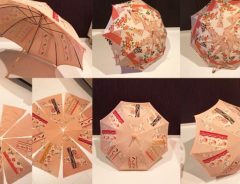

Japanese Brand Turns Worn-Out Kimonos Into Individually Crafted Sun Umbrellas

-

Somemoyou kimono & obi illustration exhibition: When modern meets traditional [report]

-

New Three Step, One Minute Prep Yukata Pajamas Look Like The Real Deal

Between the threading, the dyeing, the weaving, the sewing, and everything in between “the complexity of each step is mind boggling”, explains Sheila Cliffe.

Sheila Cliffe, for JAPAN Forward

A question I am always asked is “Why are kimono so expensive?” One day I tried asking the question to my Japanese students studying in my kimono class and one student replied, “They are sewn by hand”.

At least she had thought about the answer, and the answer is true. In most cases kimono are sewn by hand. However, sewing by hand takes the last day, or possibly two, of a process that can take upto or even more than a whole year.

© JAPAN Forward

This article will cover the making of a silk kimono, which is the main material for couture kimono. But kimono can also be made in linen, cotton, polyester and wool. Mainly the discussion is about the production aspect of kimono, but the antiquated distribution system is also responsible for the price of kimono.

Starting with the Threads

The world of silk kimono is divided into two large sections, dyed kimono and woven kimono. Of course, all kimono are woven and dyed, but the order in which these processes take place makes a significant difference in the formality of the kimono.

Dyed kimono have the pattern put on white bolts of cloth, but woven kimono have the threads dyed and are then woven together. So dyed kimono are dyed last, and woven kimono are woven last.

White thread for dyed kimono (L) Dyed thread for woven kimono (R) | © JAPAN Forward

Dyed kimono have the pattern or plain color dyed onto a bolt of white fabric. The kimono may be plain, shaded, have an all-over repeated pattern or have a pattern drawn and painted on or even embroidered on, but the key point is that the pattern is applied or produced on white fabric.

(...)

Written by Japan ForwardThe continuation of this article can be read on the "Japan Forward" site.

[Kimono Style] Why are Kimono so Expensive?