- Tags:

- Design / grooves / manufacture / Toothpicks

Related Article

-

Japanese felt artist continues to craft adorably realistic cat frames

-

Japanese designer creates incredibly realistic cuddling cat dolls with flesh and bone structure

-

Tradition And Technique Meet In New Japanese Match Style Incense Sticks

-

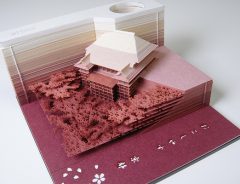

Astonishing Memo Pads Reveal Intricate Embedded Models The More You Use Them

-

Twitter Thread Spells Out Small But Pleasant Surprise Conveniences Taken For Granted In Japan

-

Origami inspired pet houses will give your furry friend a stylish abode

Toothpicks are a very convenient tool. In addition to doing what their name implies, they have all manner of practical applications unrelated to food, such as pushing reset buttons on electronic devices, unclogging glue caps, cleaning hard-to-reach places, and the like.

In Japan, they're often included in disposable chopstick packages distributed at convenience stores as well as most places selling bento lunch boxes.

Another thing you've probably noticed about Japanese toothpicks is that they usually have grooves in them at the thicker end. Hand-made premium toothpicks may have no grooves in them but almost all mass-produced toothpicks made in Japan do.

Have you ever wondered what those grooves are for?

Many people, both in Japan and elsewhere, break off the ends of Japanese toothpicks to either show that they're finished using them or as a rest to keep the soiled part from touching the table. Since this is a common practice, those who do this or have seen others do it often assume that the grooves are explicitly designed with this use in mind.

The person in charge of the Twitter account at Japanese toothpick manufacturer 菊水産業株式会社 Kikusui Sangyo Corporation (@kikusui_sangyo) felt the need to set the record straight.

When I tell people that I'm in the domestic toothpick manufacturing business, there's a 95% probability that they say: 'You break them off and use the grooves as toothpick rests, right?' with a smug expression on their face. Actually, that's wrong?

※※※※※※※※※※※※

※ JUST A DECORATION ※

※※※※※※※※※※※※

Reproduced with permission from 菊水産業株式会社 Kikusui Sangyo Corporation (@kikusui_sangyo)

In case the nuance of the translation isn't clear, they're saying what's "wrong" is the assumption that breaking them and using the grooved ends as rests is the reason the grooves were put there, and not that it's wrong for you to use toothpicks in that way if you want to.

But why decorate a toothpick with grooves in the first place?

How Japanese toothpicks got their grooves

Putting grooves on toothpicks in Japan dates back to around the 1950s.

Manufacturers at the time started off with thin shafts of white birch twice as long as the toothpicks they would eventually be made into, shaved them thin at both ends, and then cut them in the center to make two toothpicks.

However, this method often caused the cut surface, which would become the head, to become frayed and prone to splitting, and resulting in damaged toothpicks.

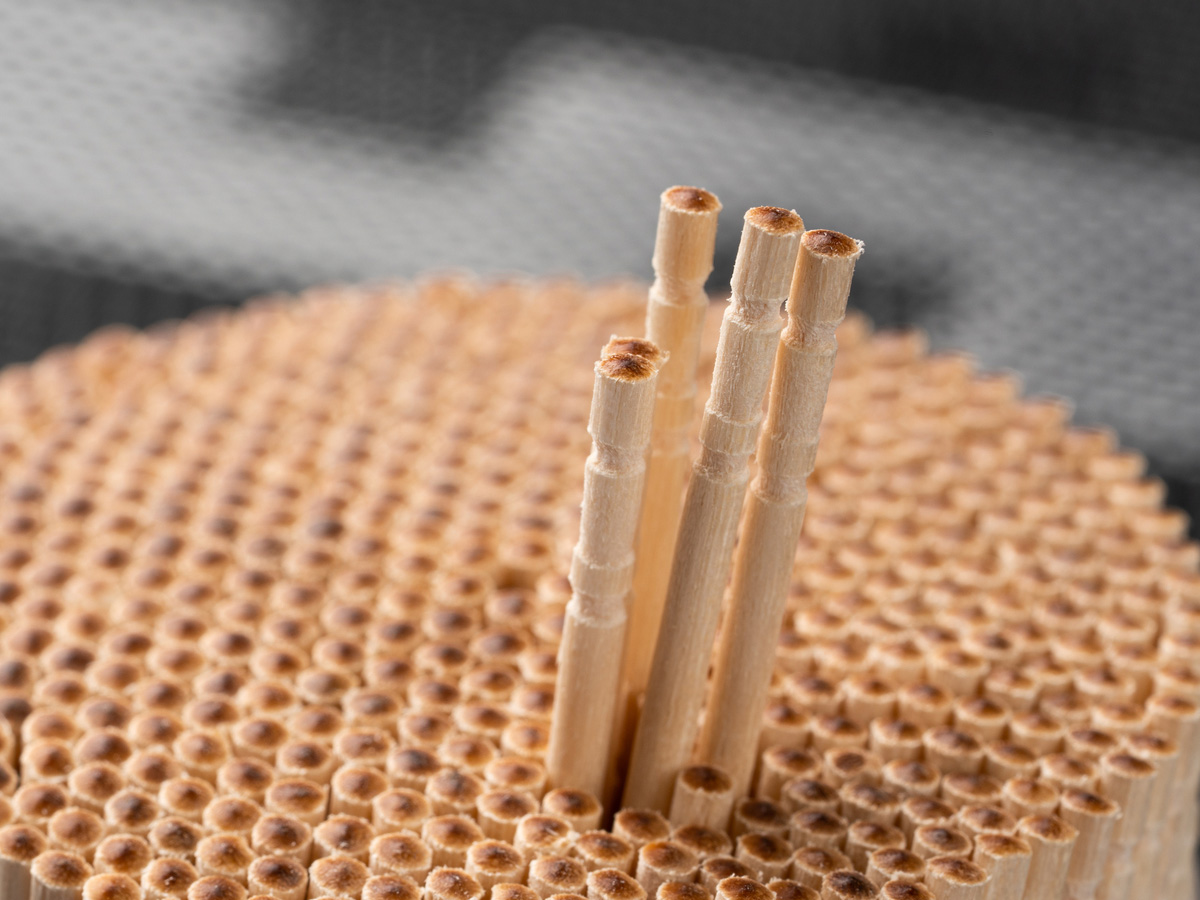

To resolve this problem, they thought of smoothing the heads with a high-speed rotary grinder. However, this had one disadvantage to it. While the heads became smooth, the frictional heat this generated caused them to burn and turn black.

Toothpick manufacturers were worried that this gave toothpicks a dirty appearance and that they may not sell well as a result. As they were looking for a solution, someone in the industry was inspired by a kind of traditional wooden doll called a 小芥子 kokeshi. In modern times, they have become more decorative, as you can see below, but they are always simple in shape with no arms or legs.

Kimivanil, CC BY-SA 4.0, via Wikimedia Commons

Their idea was they could overcome the negative image if they could make the toothpick look a bit like a kokeshi doll with a black head. Using a grinder with an uneven notched surface, they created a prototype with grooves, and the design was accepted.

Since then, it became widely adopted, resulting in the design preferred by most Japanese manufacturers to this day.

Here are the grinding stones Kikusui Sangyo uses to accomplish the task:

Reproduced with permission from 菊水産業株式会社 Kikusui Sangyo Corporation (@kikusui_sangyo)

Whether you use them as rests or don't, there's one good reason for breaking your toothpicks when you're throwing them in the trash: You don't want anyone getting pricked if they poke out of the plastic trash bag.